These acrylic emulsion is suitable for a binder of coartings and adhesives.

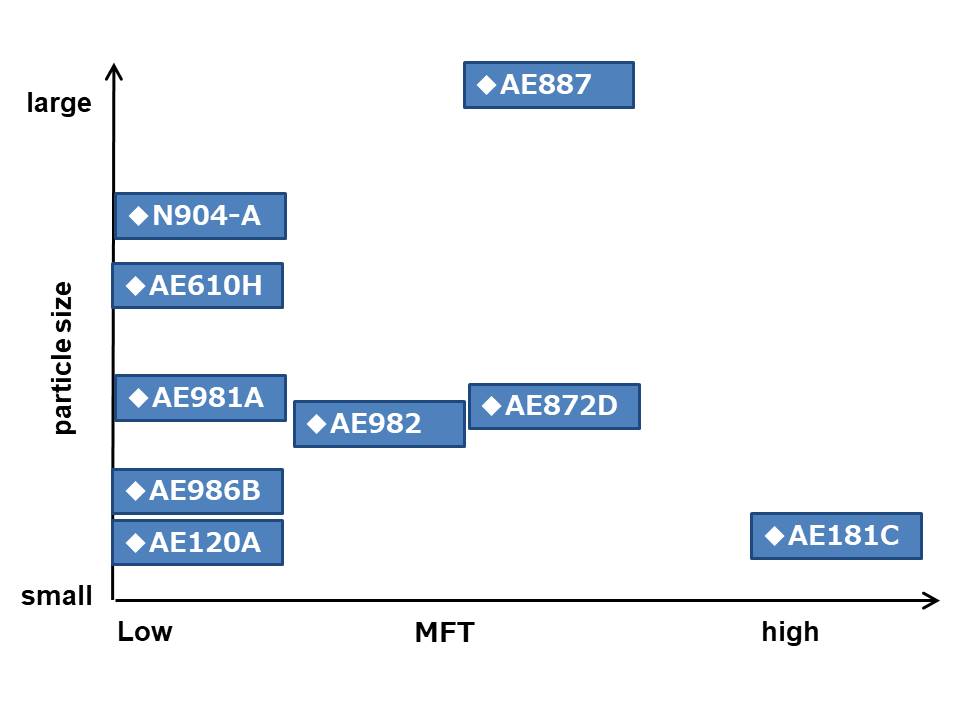

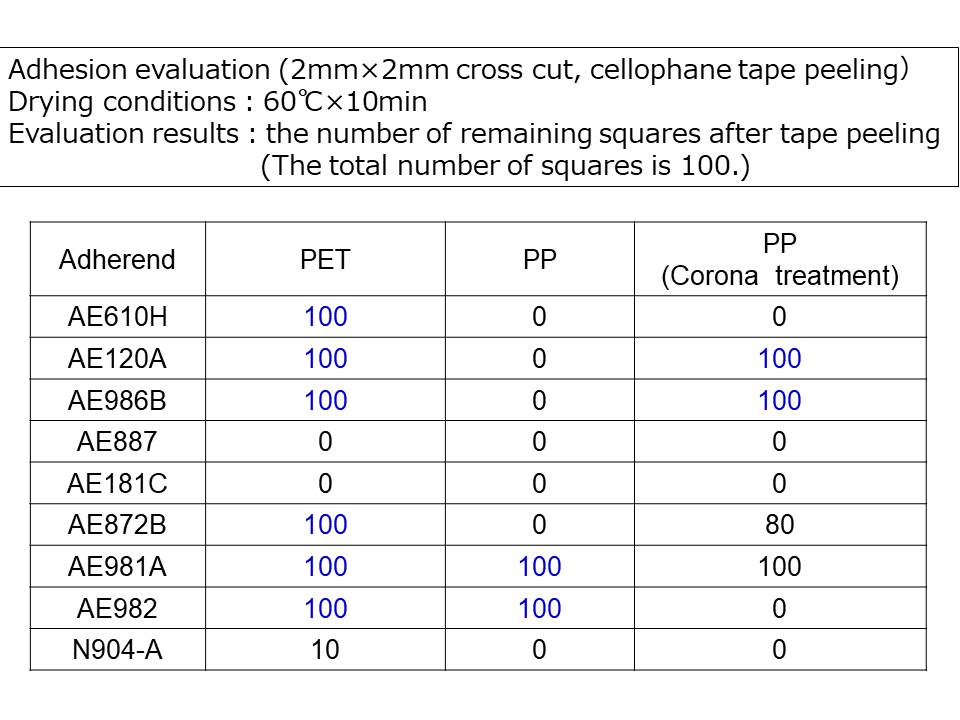

- Adhension : The close adhesion to various base materials has been improved by designing the emulsion with low Tg and surface modification.

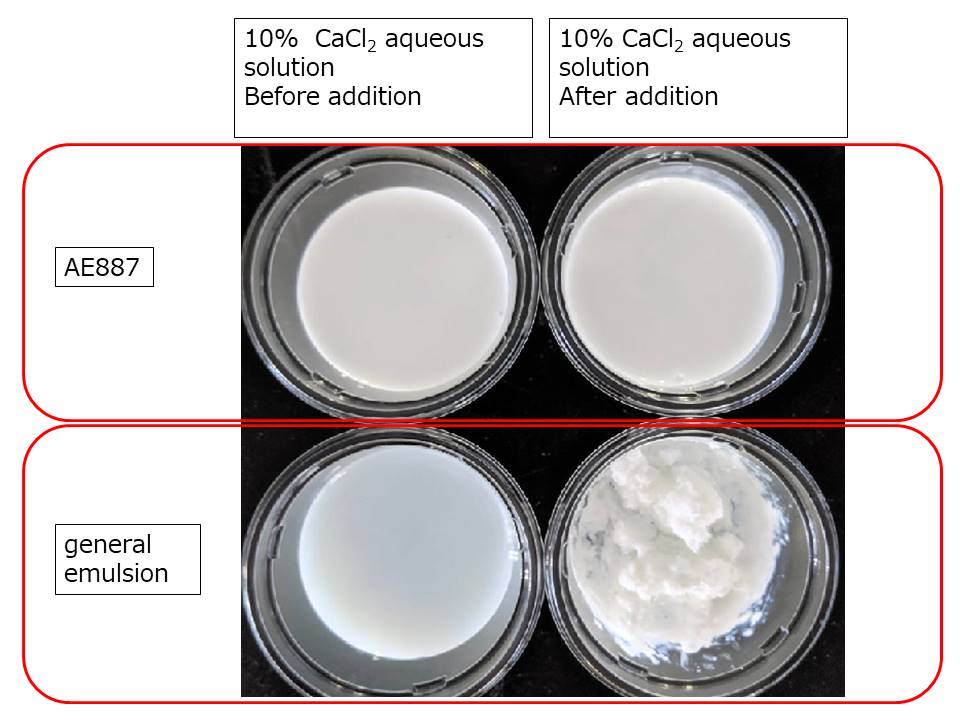

- Admixture stability : The mixing stability with other resins and fillers has been improved by selecting the type of emulsifier and surface denaturation.