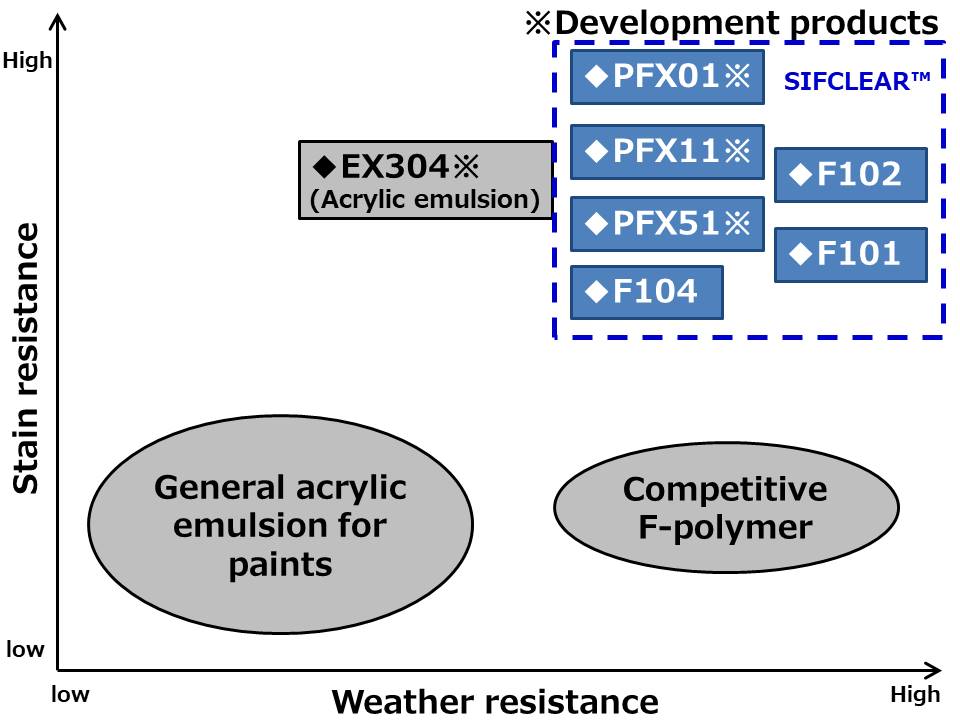

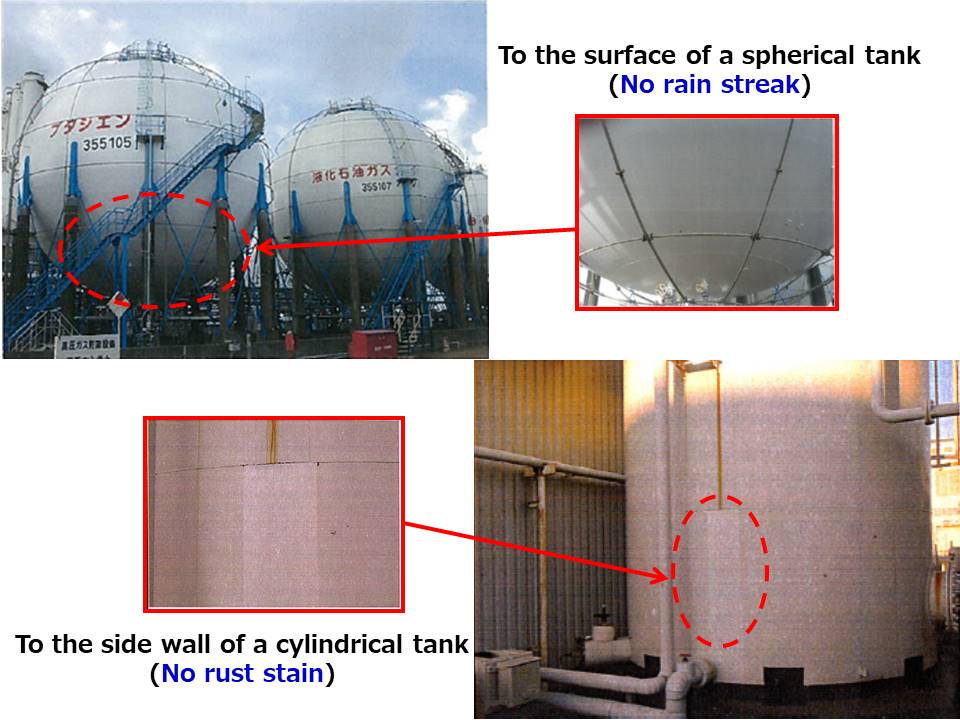

SIFCLEAR™ is a water-based modified emulsion, obtained by alloying the vinylidene-fluoride polymer with the acrylic polymer at molecular level. It can be suitably used as a binder resin of waterborne paint for the exterior walls and roofs, anti-corrosive paint system, and thermal insulation paint. Characteristics of SIFCLEAR™ are as follows.

- High transparency

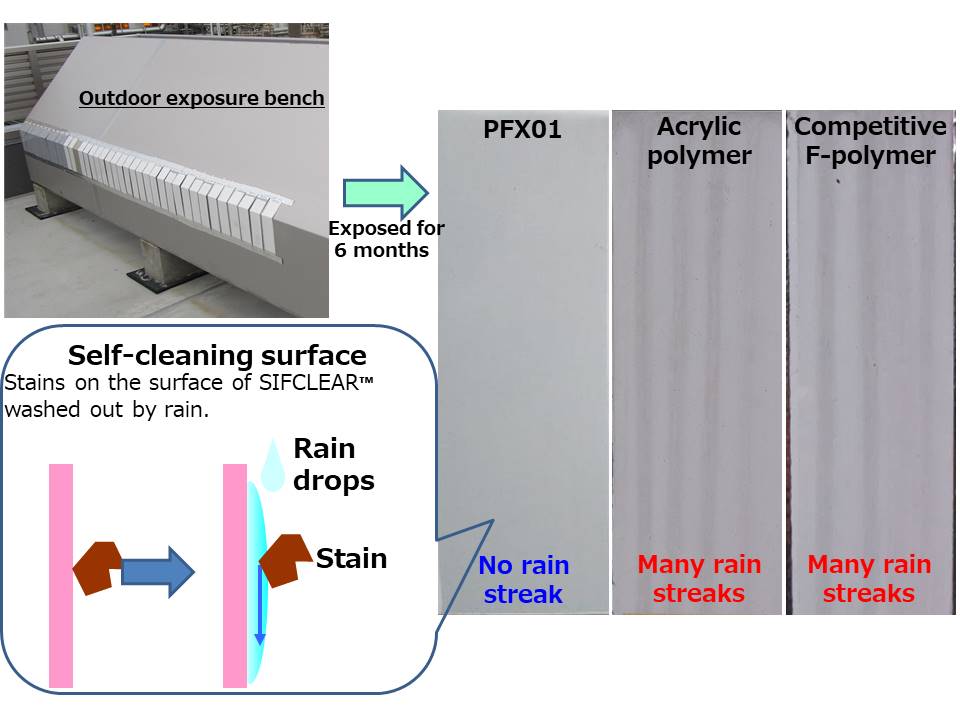

- Good water wettability

- Outstanding stain-resistance

- High weather resistance

- Excellent flexibility and adhesion

| |

F101 |

F102 |

F104 |

PFX01 |

PFX11 |

PFX51 |

|

Liquid properties

|

Total solid content (%)

|

47 |

47 |

47 |

47 |

47 |

47 |

| pH |

8 |

8 |

8 |

8 |

8 |

8 |

|

Viscosity (mPa・s) 25°C

|

1000 |

200 |

600 |

600 |

200 |

100 |

|

Particle size (nm)

|

150 |

150 |

130 |

130 |

150 |

120 |

|

Film properties

|

MFT(℃) |

50 |

<10 |

<10 |

35 |

20 |

20 |

|

Water contact angle (°)

|

85 |

90 |

75 |

75 |

N/A |

85 |

| Gross(60°) |

78 |

75 |

85 |

75 |

75 |

84 |

|

Total light transmittance (%) @30um

|

90 |

92 |

91 |

91 |

91 |

91 |

|

Elongation (23℃/-10℃)

|

470%

/2% |

440%

/100% |

260%/

75% |

50%/

N/A |

120%/

N/A |

450%/

N/A |

| Durability |

Weather resistance (XWOM 2000h)

|

100% |

85% |

90% |

91% |

95% |

95% |

|

Water resistance ⊿L 50℃ x 24h

|

0 |

0.5 |

2 |

0.5 |

1 |

1 |

|

Acid resistance 5% H2SO4×24h

|

○ |

○ |

○ |

○ |

○ |

○ |

|

Alkali resistance 5% NaOH×24h

|

○ |

○ |

○ |

○ |

○ |

○ |

| Features |

High elomgation |

High elomgation |

High gross |

High blocking resistance |

High blocking resistance |

High gross |

| Application for paint |

Siding board |

Repainting |

Repainting |

Siding board |

Repainting |

Anticorrosion |

《Test methods》

①Coat the resultant solution onto a substrate with an applicator

②Bake the film under appropriate temperature (see below).

Air drying ; 23℃ x 7 days

Baking ; 120℃ x 10min

| Resin film evaluation |

Paint evaluation |

Tensile test

Sample: Clear film (200um-thickness;air drying 23℃ x 7 days)

Dumbbell shape: No. 7

Test pieces are conditioned at 23 ℃55%RH for 3 days prior to testing.

Equipment: SHIMADZU Corporation, AUTOGRAPH AG-X

Load cell: 1kN

Distance between chucks:20mm

Measuring temperature:23℃/-10℃

Tensile speed: 50 mm/min |

Accelerated weather resistance (XWOM)

Equipment: SUGAR TEST INSTRUMENTS Co., Ltd. , Xenon Weather Meter SX-75

– Irradiance: 60 W/m2 at 300-400nm

– Black panel temperature: 63 degC

– Cycle of 2-hour duration; 102 minutes light, followed by 18 minutes light together with water spray |

Water resistance

Substrate:glass

Color difference ΔL after 24hours in hot water of 50℃. |

Acid resistance

Substrate:glass

measure color difference ΔE after 24hours in 5% H2SO4 of r.t..

○ shows that ΔE is less than 2. |

Contact angle

Equipment: Kyowa Interface Science Co., Ltd, DropMaster-500

Measurement condition: room temperature (23-25 ℃)

Droplet volume: 3 uL |

Alkali resistance

Substrate:glass

measure color difference ΔE after 24hours in 5% NaOH of r.t..

○ shows that ΔE is less than 2. |

Stain resistance (Outdoor exposure)

Outdoor exposure facing south in Yokkaichi plant; Color difference (ΔE) of 45°-side and rain streak-like stain of 90°-side are evaluated. |

|

EMULSION TECHNOLOGY CO., LTD.

Functional Chemicals Dept., Functional Chemicals Division

TEL : [81]3-6218-3841

Email : info@etec.jsr.co.jp