- Environment-friendly emulsion without organic solvents.

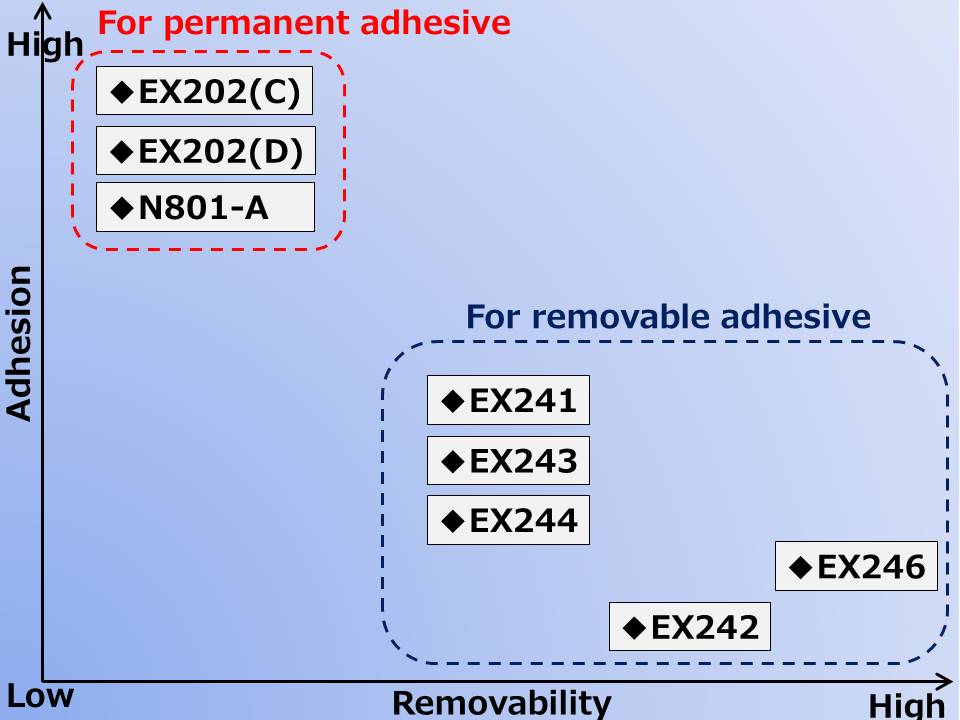

- A wide range of adhesive performance is materialized by our water-based polymerization technology.

- Removability can be imparted by adding a crosslinker. (Epoxy, Carbodiimide etc.)

- There are also improved samples for water resistance which is a common weakness of water-based PSAs (pressure-sensitive adhesives).

- Please contact us if considering switching PSAs from solvent based to water-borne.

Achieve your needs with E-TEC

--- Emulsion Technology’s environment-friendly special purpose and solvent-free materials

Water-based acrylic pressure-sensitive adhesives

Product outline

Grade comparison chart

Characteristics

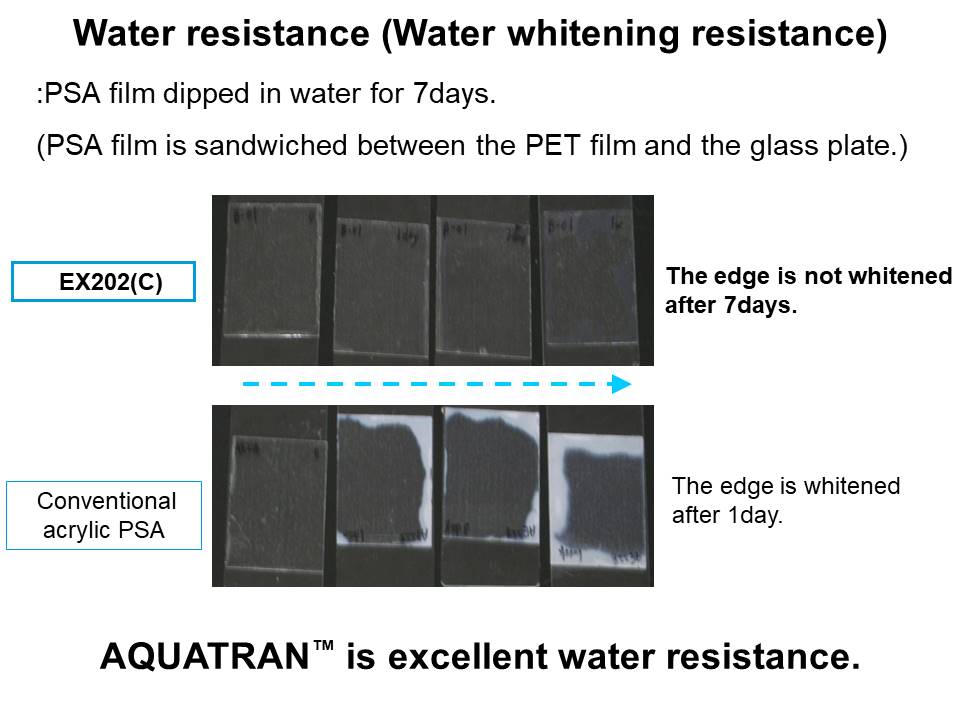

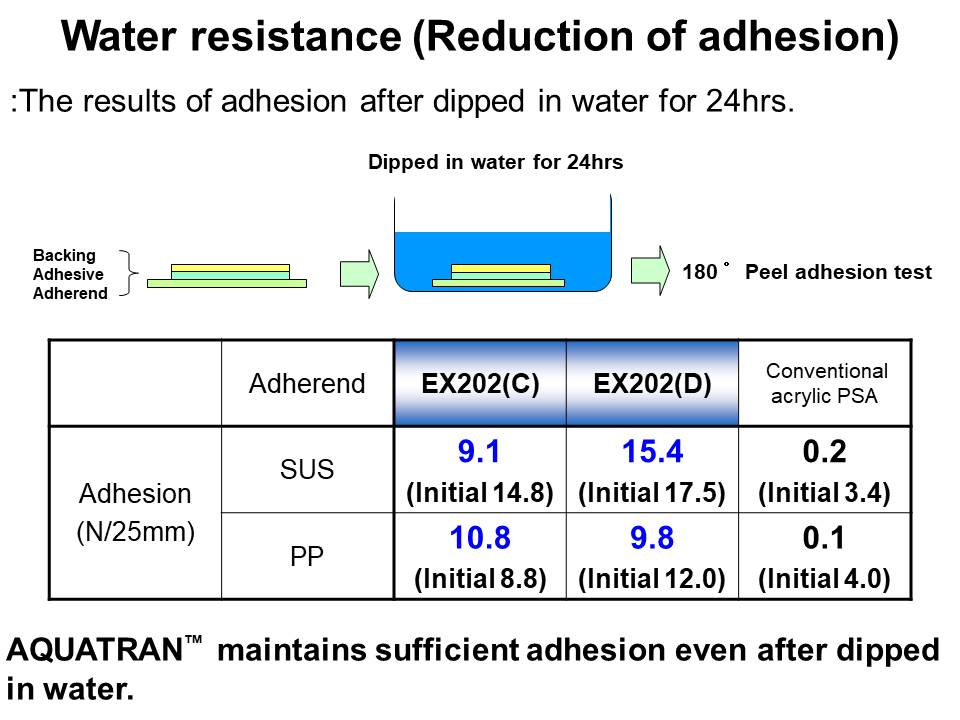

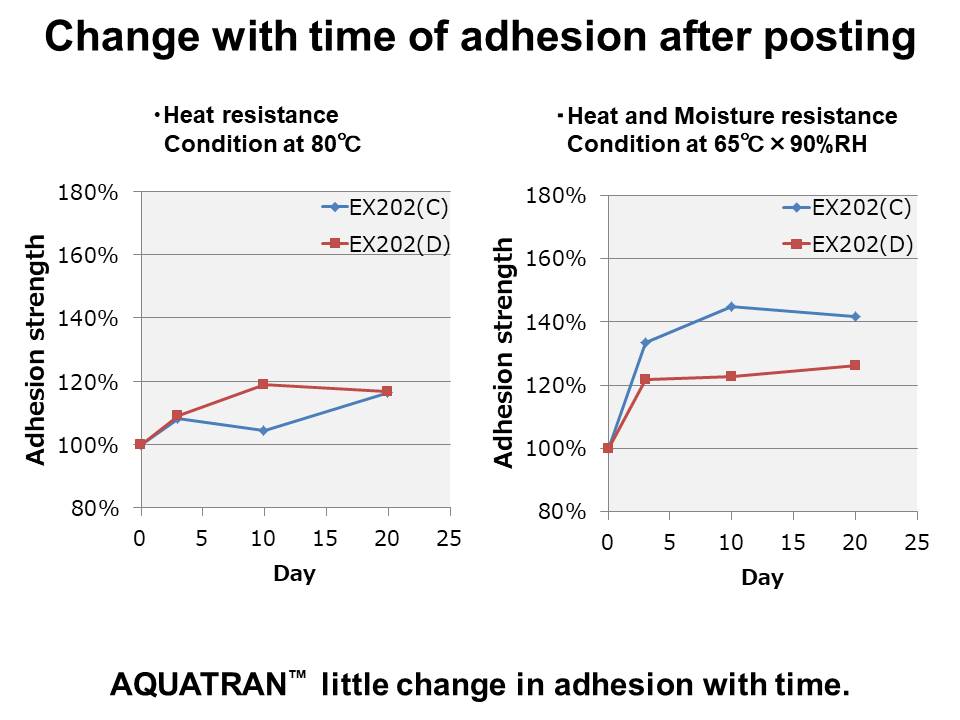

AQUATRAN™ has greatly improved water resistance compared to conventional water-borne PSAs.

Transparency and adhesiveness are retained even if getting wet.

- AQUATRAN™ can be applied to wet surfaces.

- Suggested applications are for outdoors, window film, and for wet area.

Properties

| Removable adhesive | Permanent adhesive | ||||||||

| EX243 | EX244 | EX242 | EX246 | EX241 | N801-A | AQUATRAN™ EX202(C) |

AQUATRAN™ EX202(D) |

||

| Features | Middle range adhesive | Middle range adhesive | Weak range adhesive | Weak range adhesive | Good adhesion to PVC | High range adhesive | Water resistance | Water resistance | |

| Total Solid Contents(%) | 50 | 45 | 52 | 57 | 50 | 53 | 45 | 50 | |

| Viscosity @25℃(mPa・s) |

5,500 No.4 ×60rpm |

4,000 No.4 ×60rpm |

12,000 No.4 ×6rpm |

12,000 No.3 ×6rpm |

5,800 No.4 ×60rpm |

13,000 No.4 ×12rpm |

13,000 No.4 ×6rpm |

13,000 No.4 ×6rpm |

|

| pH | 8.0 | 8.0 | 8.5 | 7.0 | 8.0 | 8.0 | 8.0 | 8.0 | |

| Adhesion to SUS (N/25mm) |

without crosslinking | 6.4 | 6 | 5.7 | 5.2 | 7.9 | 13.9 | 14.8 | 17.5 |

| with crosslinking | 3.4 | 2.6 | 3.2 | 3.9 | 6.3 | N/A | N/A | N/A | |

| Holding power (min) |

without crosslinking | 15 | 420 | 30 | >1440 | 70 | >1440 | >720 | >720 |

| with crosslinking | >1440 | >1440 | >1440 | >1440 | >1440 | N/A | N/A | N/A | |

| Ball tack (Ball No.) | without crosslinking | 24 | 21 | 20 | 22 | 15 | 20 | 6 | 10 |

| with crosslinking | 10 | 9 | 13 | 22 | 15 | N/A | N/A | N/A | |

<Testing method>

|

●Preparing test pieces (EX241~246, N801-A) ●Preparing test pieces (EX202) |

●180° peel adhesion ●Ball tack Method:J.Dow Method(θ=30°) ●Holding power |

Main markets

- Masking tape (for automobile painting, construction painting, sealing)

- Label

- Double sided tape (for fixing automobile interior components)

- Form tape (for urethan form, acryl form)

Contact

EMULSION TECHNOLOGY CO., LTD.

Functional Chemicals Dept., Functional Chemicals Division

TEL : [81]3-6218-3841

Email : info@etec.jsr.co.jp