- It’s a new urethane adhesive that achieves both high level elongation and strength.

- While having the equal level of strength as epoxy adhesives, it also has high strain relaxation, which provides more flexible material design.

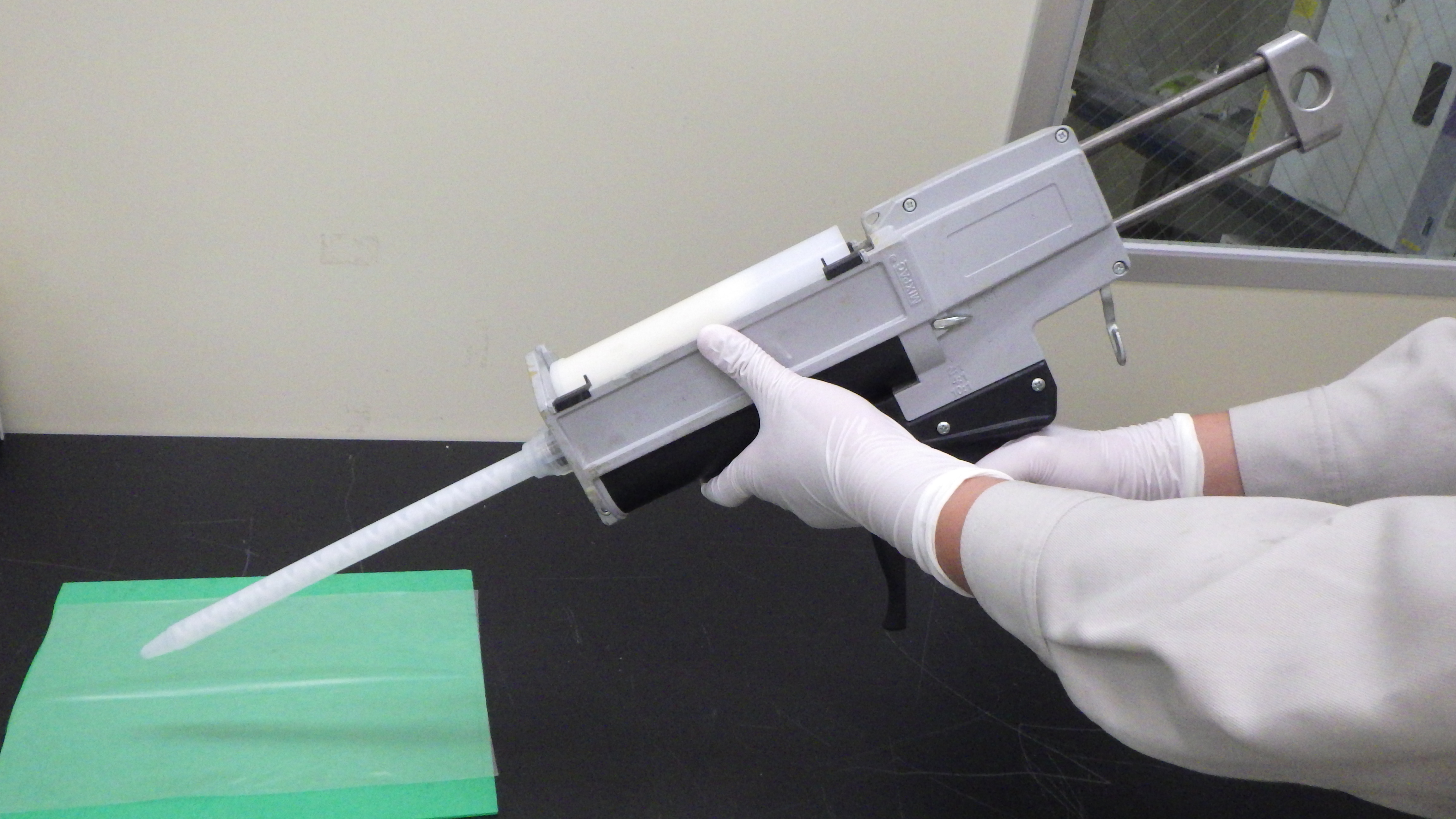

- Using cartridge gun provides a simple bonding workability.

Achieve your needs with E-TEC

--- Emulsion Technology’s environment-friendly special purpose and solvent-free materials

High Elongation and High Strength Adhesive MIGHTYGRIP™5200 【MIGHTY Series】

New product of Urethane adhesives that achieves both high level elongation and strength.

Product outline

Property

-

Compatibility of elongation and strength

Although “Elongation” and “Strength” of urethane adhesives were traded off within the conventional technology, our unique technology has realized a combination of high level elongation and strength. Our product has high elongation of urethane adhesive and strong adhesive force equivalent to epoxy adhesive.

-

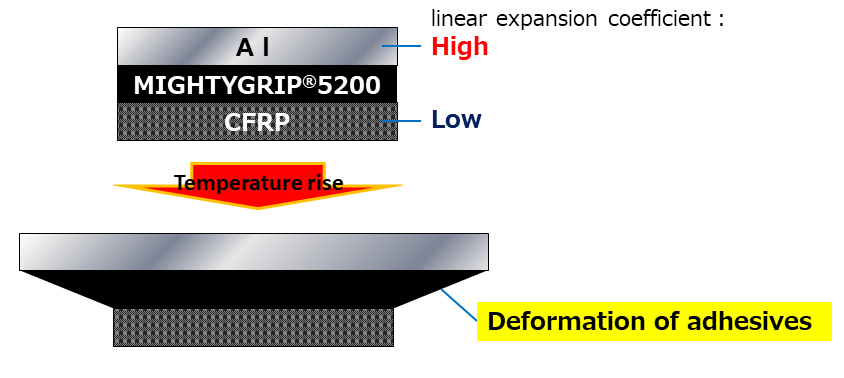

Realization of more free material design

MIGHTYGRIP®5200’s elongation is able to relax various strain stresses applied to the adhesives even it holds the highest level of adhesive strength among our urethane adhesives. Especially, it exhibits a high relaxation effect for the deterioration of the appearance during the curing process of the adhesive and the thermal strain when bonding dissimilar materials.

-

Corresponds to cartridge guns

Using cartridge gun provides a simple bonding workability.

Product lineup

| Series | MIGHTYGRIP 5200 series High Elongation and High Strength Adhesive | High hot strength Adhesive | ||||||||

| Features | Standard type ・Can be cured at room temperature and heat-cured also. |

High elongation type(prototype) ・Can be cured at room temperature and heat-cured also. |

High hot strength (prototype) ・Can be cured at room temperature(Post cure recommended). |

High hot strength (prototype) ・Heat-cure required |

||||||

| Properties of uncured products | Product Name | Resin | Hardener | Resin | Hardener | Resin | Hardener | Resin | Hardener | |

| MG5200 | MG5210 | MG5200 | B611 | A621 | B621 | A621 | B631 | |||

| Viscosity(Pa・s) at25℃ | 51 | 20 | 51 | 36 | 34 | 26 | 34 | 27 | ||

| Specific gravity at25℃ | 1.25 | 1.27 | 1.25 | 1.12 | 1.23 | 1.11 | 1.23 | 1.16 | ||

| Mixing ratio (Parts per weight) | 100 | 100 | 190 | 170 | 110 | 100 | 170 | 160 | ||

| Tack-free time(min) | 10 | 13 | 13 | 20 | ||||||

| Adhesive properties * |

Curing Condition | 23℃×72h | 23℃×72h | 80℃×4h | 80℃×4h | |||||

| Lap shear strength(MPa) | 23℃ | 30 SF | 25 SF | 27 SF | 18 SF | |||||

| 80℃ | 7 CF | 6 CF | 11 CF | 21 SF | ||||||

| -30℃ | ND | ND | ND | ND | ||||||

| Properties of cured products | T-Peel strength (N/25mm) | 23℃ | 180 | ND | ND | ND | ||||

| Elongation at break (%) | 270 | 420 | 190 | 6 | ||||||

| Young’s modulus (MPa) | 100 | 20 | 500 | 1200 | ||||||

| Tensile strength at break (MPa) | 22 | 21 | 24 | 60 | ||||||

| Shore-D hardness | 40 | ND | ND | ND | ||||||

*Substrate = ED-Steel , Failure mode : CF = Cohesive Failure, SF = Substrate Failure

Application

| Field | Application | Materials |

| Car | Spoiler, Roof, Door | CFRP/CFPR |

| Cover top, Engine hood | CFRP/CFPR, SMC/SMC | |

| Ceiling | Unwoven Fabric/Metal | |

| Vehicle | Bus Trunk lid | FRP/FRP |

| Refrigerator car Door | Aluminum/plywood | |

| Bullet train Interior (ceiling) | FRP/Aluminum | |

| House Facilities | Water purifier tank | FRP/FRP |

| Kitchen counter | Polyethylene/SUS | |

| Unit bath | Polyethylene/ABS | |

| Architecture | Water tank panel | FRP/AES |

| Automatic door | Glass/Aluminum | |

| Exterior panel | Coated metal/rook wool | |

| Swimming pool | FRP/FRP | |

| Ship, Leisure | Fishing vessel, Water scooter | FRP/FRP |

Link

Contact

EMULSION TECHNOLOGY CO., LTD.

Functional Chemicals Dept., Functional Chemicals Division

TEL : [81]3-6218-3841

Email : info@etec.jsr.co.jp