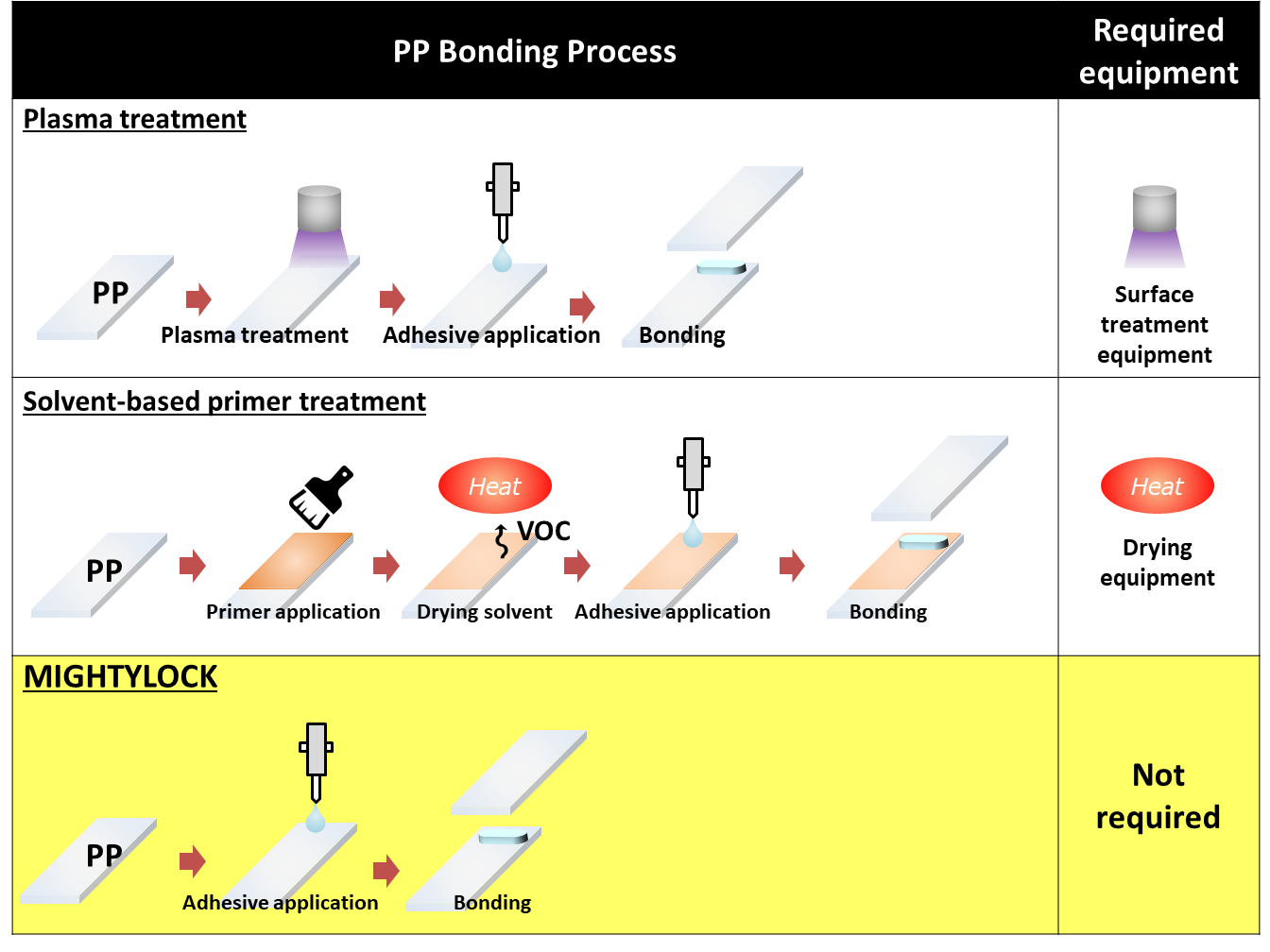

- Polypropylene, one of the hardly adhesive plastic materials, can be bonded with this adhesive alone.

- Requiring no special surface treatment helps to reduce working process and improves productivity.

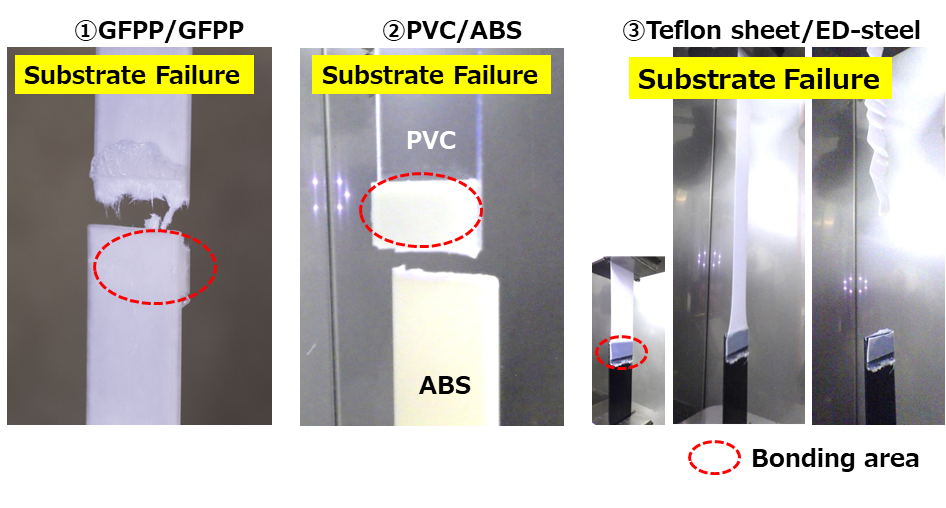

- Not only polypropylene but also various other materials can be bonded.

Achieve your needs with E-TEC

--- Emulsion Technology’s environment-friendly special purpose and solvent-free materials

Acrylic adhesive for PP MIGHTYLOCK™ 【MIGHTY Series】

Acrylic adhesive with high adhesive strength suitable for materials such as polypropylene and Teflon.

Product outline

Property

-

No special surface treatment required

-

Polypropylene (PP) is known as “hardly adhesive plastic” that requires special surface treatment before bonding. MIGHTYLOCK has achieved a strong bond to PP without surface treatments. There is no need to introduce expensive equipment or complicated processes; besides, no harmful gas such as VOC is generated. It is possible to reduce the number of working process and improve productivity.

-

Realization of more free material design

Not only PP but various other materials such as polycarbonate and vinyl chloride can be adhered strongly. In fact, the adhesive strength is so strong that causes the destruction of the specimen made by the Teflon sheet in our lap shear strength test. Our adhesive enables you to work on your material design goes beyond conventional knowledge.

-

Compatible with cartridge guns

Using cartridge gun provides a simple bonding workability.

Basic physical properties

| Series | Acrylic adhesive for PP | ||

| Features | ・Bondable to polypropylene without surface treatment ・High adhesion to various plastics | ||

| Properties of uncured products | Product Name | Activator | Resin |

| G7010C248-1 | G7010C353-2 | ||

| Viscosity(Pa・s) at25℃ | 1.5 | 10 | |

| Specific gravity at25℃ | 1 | 1 | |

| Mixing ratio (Parts per weight) | 1 | 10 | |

| Mixing ratio (Parts per volume) | 1 | 10 | |

| Curing Condition | 23℃×24h | ||

| Adhesive properties | Lap shear strength(MPa)*1 | GF-PP:11 SF | |

| T-Peel strength (N/25mm)*2 | 100 | ||

| Properties of cured products | Elongation at break (%) | 8 | |

| Young’s modulus (MPa) | 320 | ||

| Tensile strength at break (MPa) | 12 | ||

| Shore-D hardness | 52 | ||

*1 Failure mode : SF = Substrate Failure *2 Substrate = ED-Steel

Application

- Adhesion of automotive interior and exterior parts

- Bonding of all resin materials such as electric and electronic parts.

- Substitute for second generation acrylic adhesive (SGA), chlorinated PP adhesive, hot melt adhesive, etc.

Link

Urethane adhesive MIGHTYGRIP High Elongation and High Strength Adhesive MIGHTYGRIP 5200 Urethane-Acrylic hybrid type adhesive

Contact

EMULSION TECHNOLOGY CO., LTD. Functional Chemicals Dept., Functional Chemicals Division TEL : [81]3-6218-3841 Email : info@etec.jsr.co.jp